Rahnplastics.com hits 10,000 visitors!!

In the short time that we have opened our new Rahn Plastics Inc website, we have hit over 10,000 visitors in the first two months!!

We are overjoyed at the response the new site is generating and we have you, our customers and partners to thank for it. Your continued support and dedication to Rahn Plastics is helping us grow and develop as a world-class company, and the great interest in our website shows that we will continue to improve and provide the customer service excellence and high-quality products you have come to expect from us.

Once again, thank you for your support, and keep coming back to rahnplastics.com, we welcome any comments or feedback you may have.

What is an SDR?

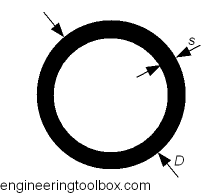

Many PE pipe and fitting manufacturers use the “Standard Dimension Ratio” – SDR – method of rating pressure piping. The SDR is the ratio of pipe diameter to wall thickness and the SDR can be expressed as:

SDR = D / s (1)

where

D = pipe outside diameter (mm)

s = pipe wall thickness (mm)

A SDR 11 means that the outside diameter – D – of the pipe is eleven times the thickness – s – of the wall.

We here at Rahn Plastics find that the most requested SDR size is SDR11. Also common are DR’s 9 and 17. These are the industry standards however Rahn will also manufacture special DR sizes as well (eg. DR 5, DR7, DR13.5, DR15.5, DR21, DR26 etc.)

A detrimental effect of a lower DR is the flow rate reduction, while the higher DR’s have a lower pressure rating.

Our HDPE resin is PE 4710 which are produced from bimodal resins. The benefits of PE 4710 fittings made from these materials are characterized by truly exceptional and unique resistance to slow crack growth (SCG), significantly improved long term performance, higher pressure ratings or increased flow capacity, and improved chemical resistance. These high performance HDPE resins give the designer another tool to make any application system more competitive and viable.